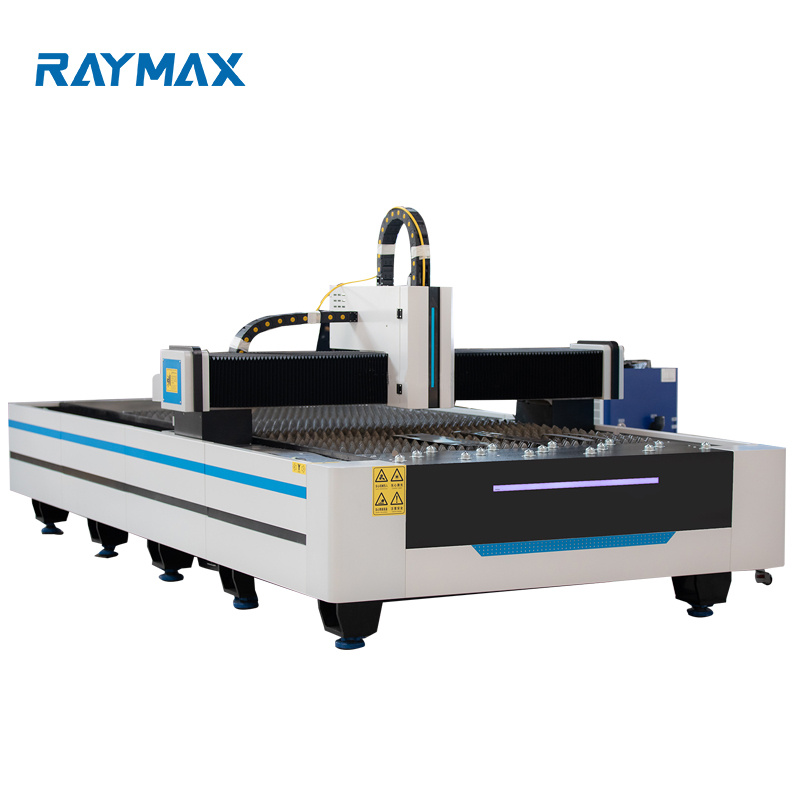

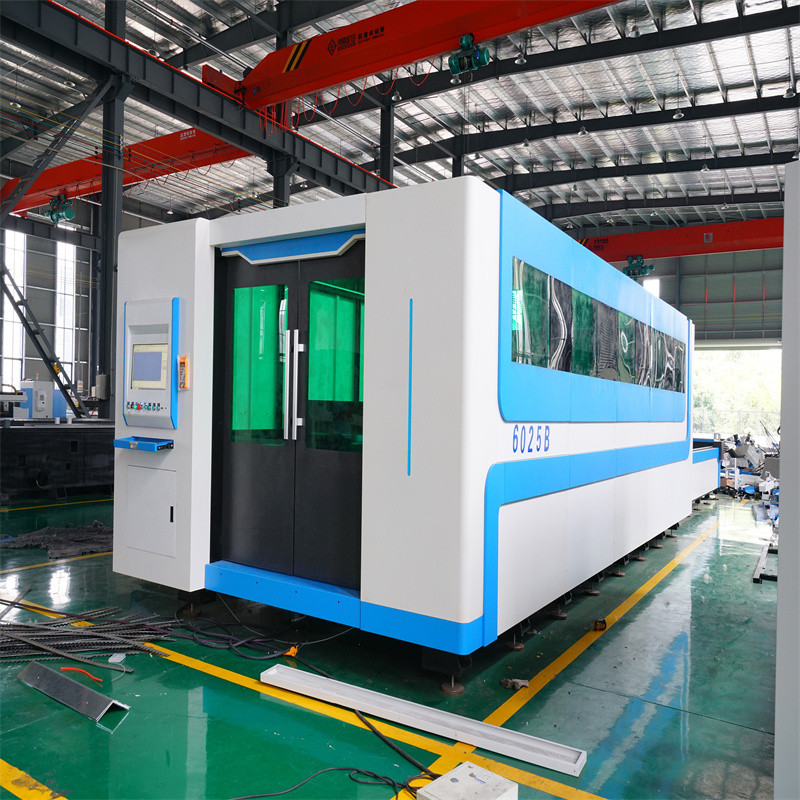

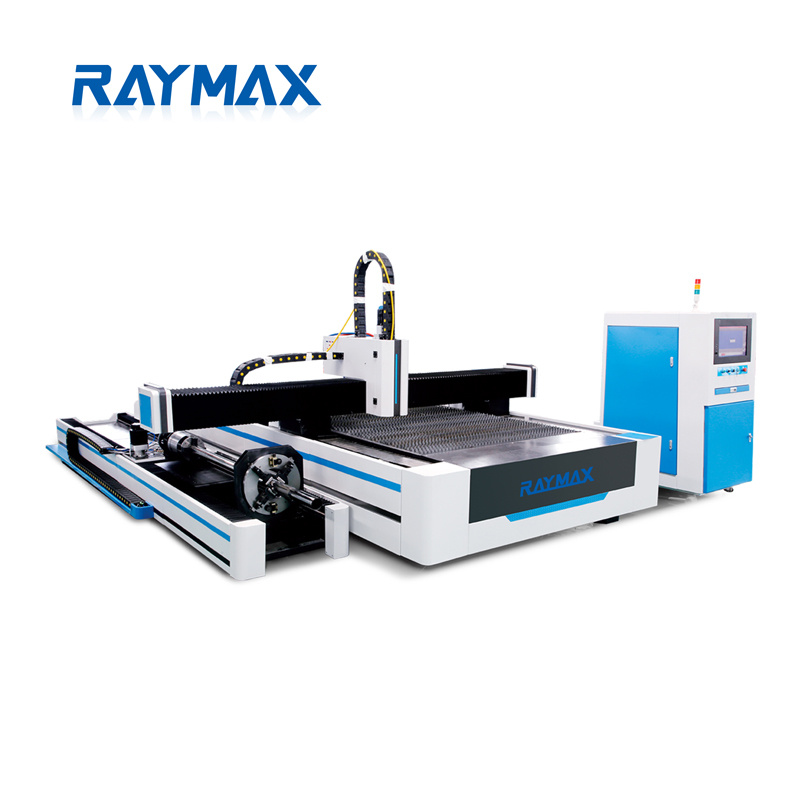

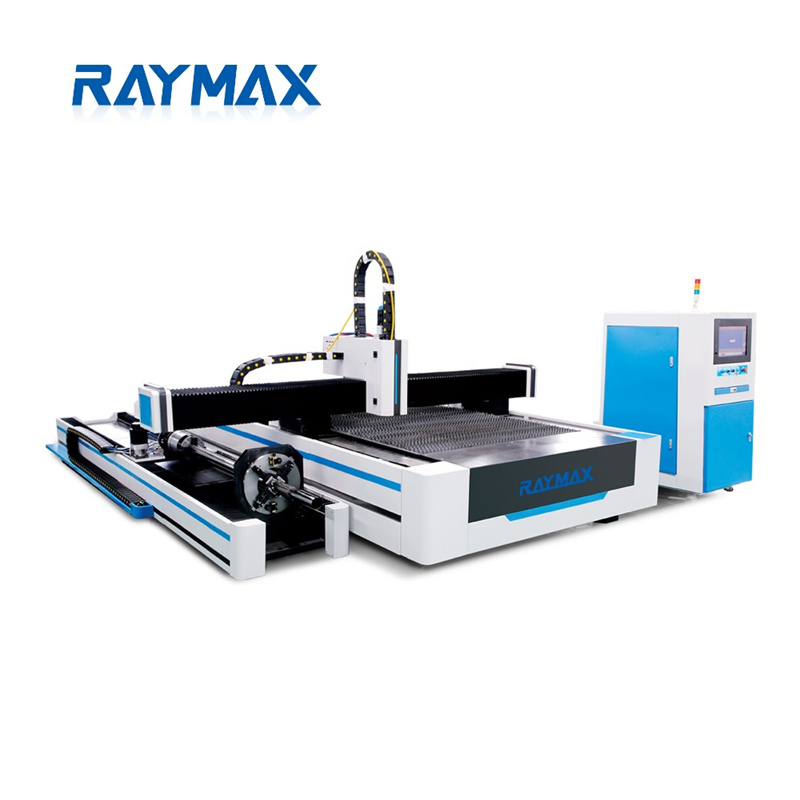

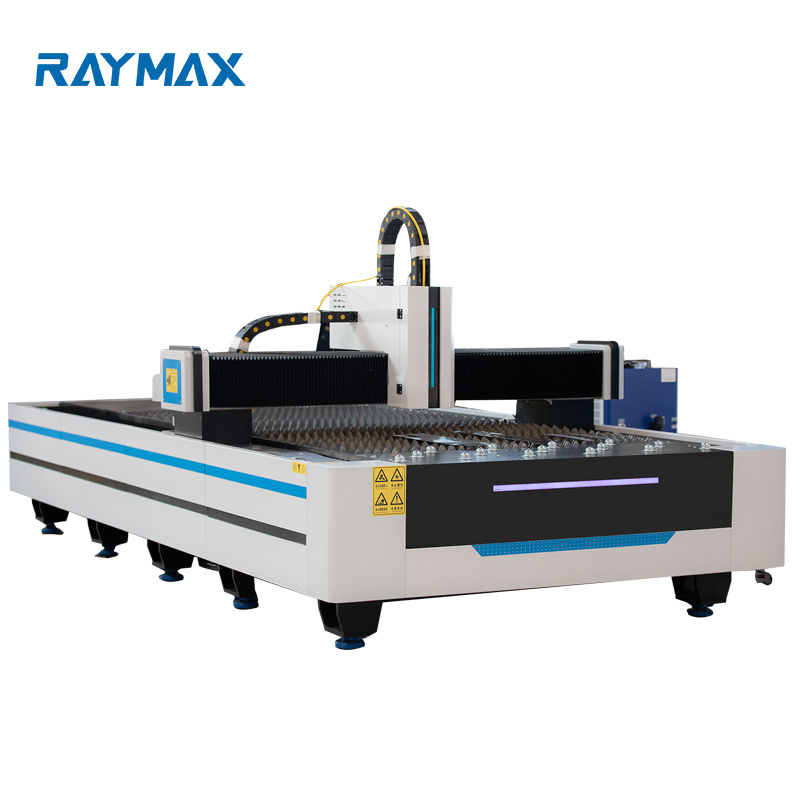

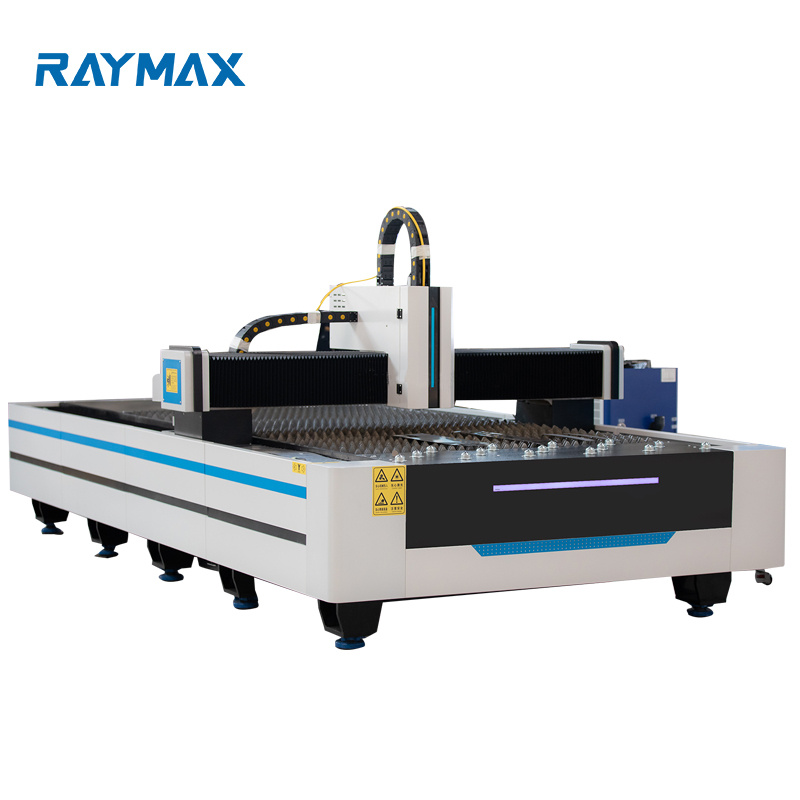

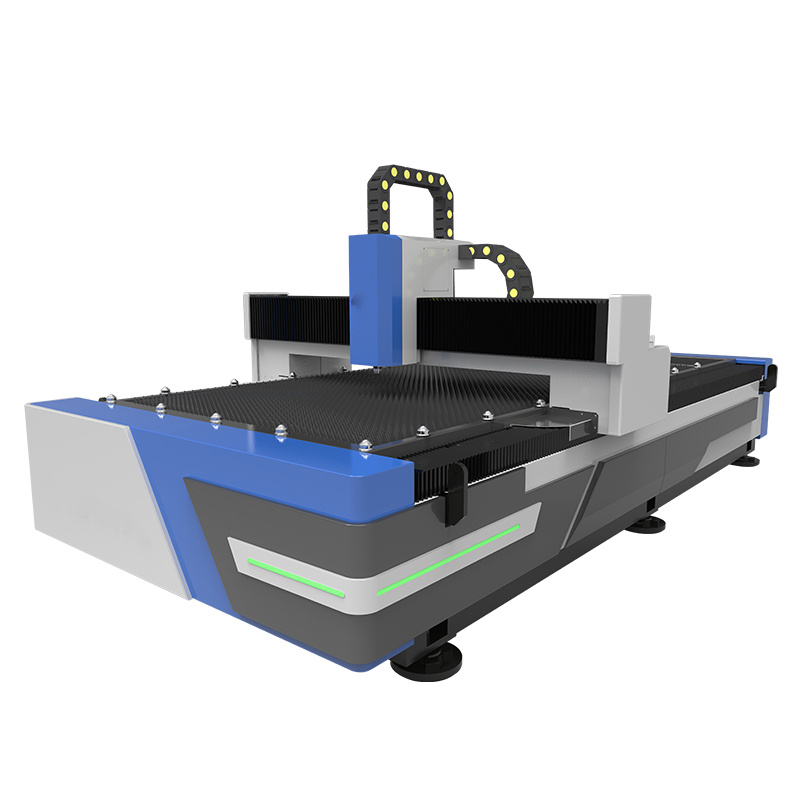

The entry-level laser cutting machine, really cost-effective, open-type, single platform, simple structure, convenient installation, high precision, fast speed, simple operation, convenient maintenance, affordable equipment, low operating cost, it is a sheet metal processing enterprise customized product.

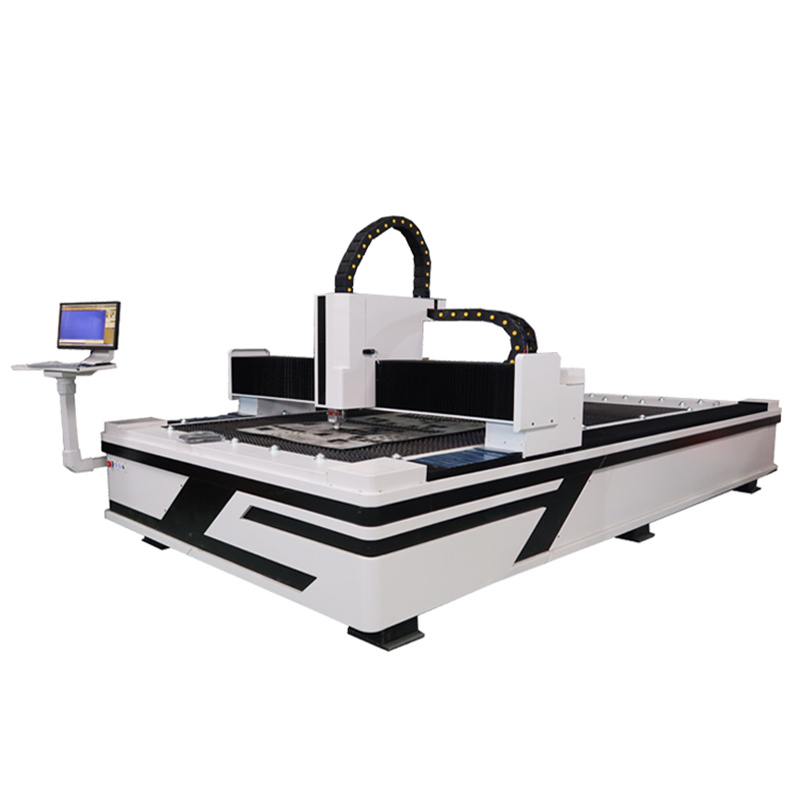

Fiber laser beams offer a metal friendly wavelength that metal absorbs more efficiently. The smaller spot size and excellent beam profile make it ideal for cutting most any metals. Most notably, compared to CO2, fiber has a straight line speed that’s 2-3x faster when cutting thin sheet metal at 5mm or less.

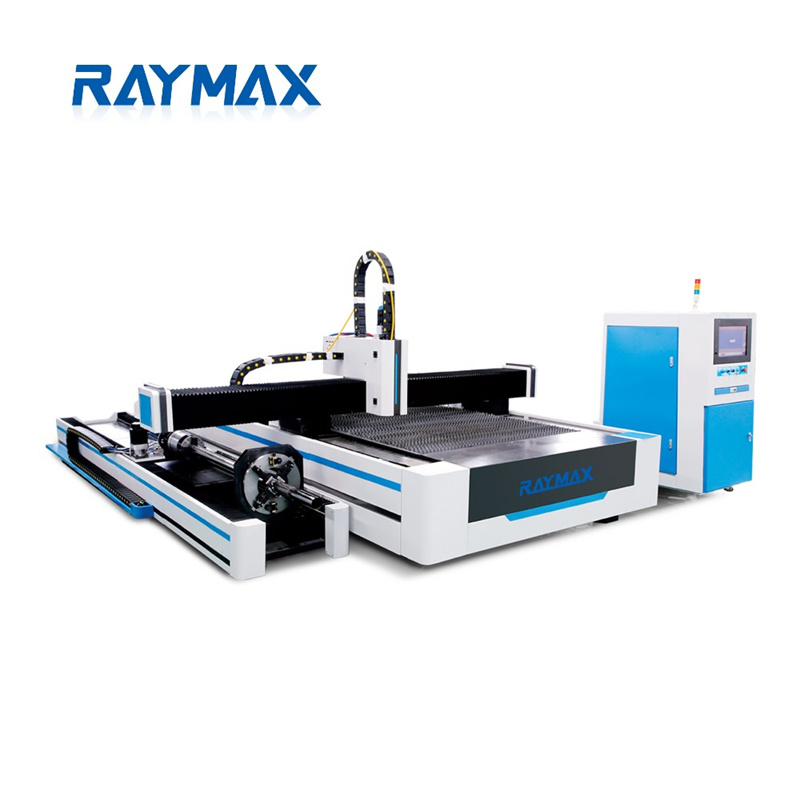

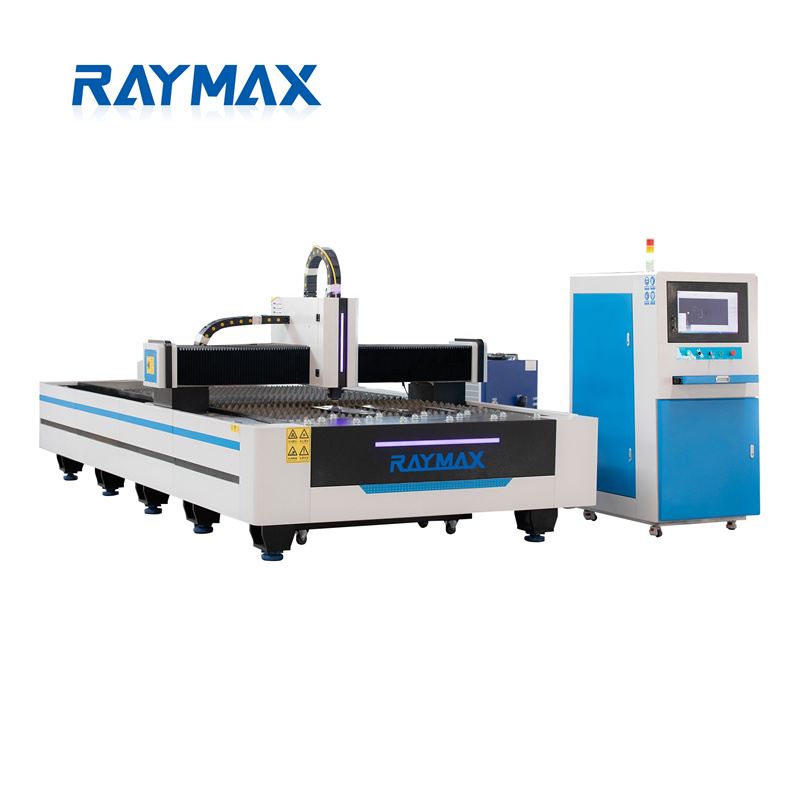

It is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickled sheet, aluminized zinc sheet, copper and other metal materials. Technical parameters Cutting widths vary and can be customized according to requirements. Cutting (backlash) speed: 0〜30000mm/min

The metal cutting machine can cut carbon steel thickness from a minimum of 1mm to 25mm.In the choice of metal laser cutting machine, we will have suggestion as below: Using a sheet metal laser cutter with a low power of about 500w for carbon steel below 3mm.