Streamllined Design, advancecl configuration, high precision and high efficiency CNC hydraulic press brake.

Electro-Iydraulic servo systern, closed loop control block synclronization.

Stand configuration with 3 1 axes Y1 (upward-downward of left cylinder), Y2 (upward-downward of right cylinder), X (fonward-backwi3rci of backgauge), V (hydraulic crowning). Backguage Optional 4 1 axes,6 1 axes or more axes according to user needs.

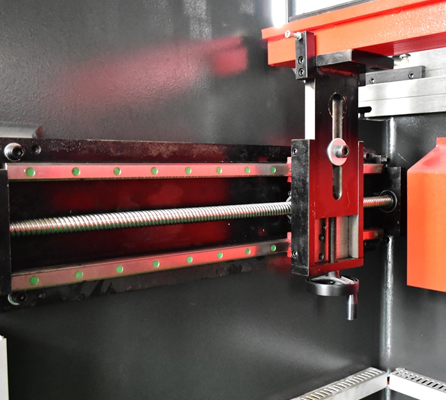

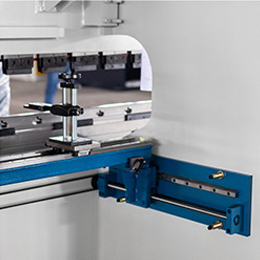

Double crowning mechanism -Upper mechanical quick fastener has both quick fastening and crowning function.Standard straight line guide rail type removable backguage, A set of standard upper and lower mold(die) with machine.

| 안건 | 공칭 압력 | 테이블 길이 | 열 사이의 거리 | 목 깊이 | 슬라이드 스트로크 | Maximum open height | distance of back gauge | 외관 크기 |

| (한) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | L*W*H (mm) | |

| 35/1600 | 350 | 1600 | 1280 | 180 | 90 | 300 | 0-400 | 1600*1300*2000 |

| 40/2500 | 400 | 2500 | 2000 | 200 | 120 | 360 | 0-400 | 2500*1350*2000 |

| 63/2500 | 630 | 2500 | 2000 | 250 | 120 | 360 | 0-600 | 2500*1480*2050 |

| 63/3200 | 630 | 3200 | 2600 | 280 | 120 | 360 | 0-600 | 3200*1480*2050 |

| 80/2500 | 800 | 2500 | 2000 | 280 | 120 | 370 | 0-600 | 2500*1510*2100 |

| 80/3200 | 800 | 3200 | 2600 | 280 | 120 | 370 | 0-600 | 3200*1550*2100 |

| 100/2500 | 1000 | 2500 | 2000 | 320 | 120 | 380 | 0-600 | 2500*1560*2200 |

| 100/3200 | 1000 | 3200 | 2600 | 320 | 120 | 380 | 0-600 | 3200*1560*2260 |

| 100/4000 | 1000 | 4000 | 3200 | 320 | 120 | 380 | 0-600 | 4000*1560*2260 |

| 125/2500 | 1250 | 2500 | 2000 | 320 | 120 | 380 | 0-600 | 2500*1560*2200 |

| 125/3200 | 1250 | 3200 | 2600 | 320 | 120 | 380 | 0-600 | 3200*1560*2260 |

| 125/4000 | 1250 | 4000 | 3200 | 320 | 120 | 380 | 0-600 | 4000*1560*2260 |

| 160/2500 | 1600 | 2500 | 2000 | 330 | 200 | 460 | 0-600 | 2500*1700*2560 |

| 160/3200 | 1600 | 3200 | 2600 | 330 | 200 | 460 | 0-600 | 3200*1700*2560 |

| 160/4000 | 1600 | 4000 | 3200 | 330 | 200 | 460 | 0-600 | 4000*1700*2560 |

| 160/6000 | 1600 | 6000 | 4800 | 330 | 200 | 460 | 0-600 | 6000*1700*2567 |

| 200/2500 | 2000 | 2500 | 2000 | 350 | 200 | 480 | 0-600 | 2500*1760*2570 |

| 200/3200 | 2000 | 3200 | 2600 | 350 | 200 | 480 | 0-600 | 3200*1760*2570 |

| 200/4000 | 2000 | 4000 | 3200 | 350 | 200 | 480 | 0-600 | 4000*1760*2800 |

| 200/6000 | 2000 | 6000 | 4800 | 350 | 200 | 480 | 0-600 | 6000*1950*2985 |

| 250/3200 | 2500 | 3200 | 2600 | 400 | 250 | 540 | 0-600 | 3200*1900*3000 |

| 250/4000 | 2500 | 4000 | 3200 | 400 | 250 | 540 | 0-600 | 4000*1900*3000 |

| 250/6000 | 2500 | 6000 | 4800 | 400 | 250 | 540 | 0-600 | 6000*1950*3140 |

| 300/3200 | 3000 | 3200 | 2600 | 400 | 250 | 560 | 0-600 | 3200*1900*3200 |

| 300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 560 | 0-600 | 4000*1950*3200 |

| 300/6000 | 3000 | 6000 | 4800 | 400 | 250 | 560 | 0-600 | 6000*1950*3250 |

| 400/3200 | 4000 | 3200 | 2600 | 400 | 250 | 560 | 0-600 | 3200*1950*3250 |

| 400/4000 | 4000 | 4000 | 3200 | 400 | 250 | 560 | 0-600 | 4000*1950*3450 |

| 400/6000 | 4000 | 6000 | 4800 | 400 | 250 | 560 | 0-600 | 6000*1950*3450 |

| 500/4000 | 5000 | 4000 | 3200 | 400 | 320 | 580 | 0-800 | 4000*2050*3620 |

| 500/6000 | 5000 | 6000 | 4800 | 400 | 320 | 580 | 0-800 | 6000*2150*3750 |

세부 이미지

Quick folding system with support bracket

adjustable Back File Material Device

High Precision CNC Die

Fast Speed Clamping Device

Back File Material Device

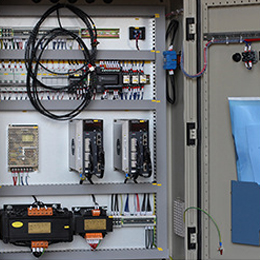

High Efficiency High Quality Motor

기름 펌프

Master Electrical Box

왜 우리를 선택 했습니까

Team

we team always can also provide overseas installation, training, maintenance, commissioning and other services for each clients,to ensure that customers can correctly operate TOF products, and enjoy high performance and the best service in operation.

Technology

we committed to the R&D and manufacture of professional equipment. With our product development capabilities, the leading level inthe industry, scheme ability, constantly updated, we are widely accept by clients from all over the world.

제품

We have been committed to the production of various specifications of metal processing machinery and equipment, such as bending machine shearing machine, hydraulic press punching machines, turret punch press, laser cutting machine, And professional door production line etc

자주하는 질문

Q: How long is the warranty of the product?

A: Product warranty: 18-24 months.During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged,those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

> We could provide technical guiding, production, installation, debugging and maintenance service to all customers. After the end of the warranty period, it's not free.

> We will provide the technical support for the whole life of the equipment.

Q. What are your terms of packing?

A: Packing: export worthy package suitable for container transportation.

PlyWooden case, iron pallet, plastic film ect.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

세부

- 슬라이더 스트로크(mm): 100mm

- 자동 레벨: 반자동

- 목 깊이(mm): 250mm

- 기계 유형: 동기화

- 작업대 길이(mm): 2500

- Width of Working Table (mm): 800 mm

- Dimension: 3100*1890*2200mm

- 조건: 새로운

- Material / Metal Processed: Stainless Steel, ALLOY, Carbon steel, Aluminum, The sheet metal

- 자동화: 수동

- 추가 서비스: 가공

- 연도: 2020

- Weight (KG): 4600

- 모터 전력(kw): 5.5kw

- 주요 판매 포인트: 다기능

- 보증: 1년

- Applicable Industries: Building Material Shops, Manufacturing Plant, door Manufacturing plant

- 기계 시험 보고서: 제공

- 영상출입검사 : 제공

- 핵심 부품 보증: 5년

- 핵심 부품: 모터, 펌프

- material: Steel (Carbon steel)

- voltage: 220V/240V/380V/460V optional

- color: optional

- Raw Material: Metal

- Power: Electric -hydraulic

- Product name: metal bending machine

- Name: bending machine

- 용법: 금속 장 회전 절단 구부리기

- 유형: 금속 벤더 도구

- 응용 프로그램: 스테인리스 판 구부리기

- After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Video technical support, Online support

- 보증 후 서비스: 비디오 기술 지원, 온라인 지원, 예비 부품, 현장 유지 보수 및 수리 서비스